-

1 Double Damask

This is not a double cloth. It is a linen fabric with one set of warp threads and one set of weft threads. The Belfast Textile Testing House gives the opinion that " the term Double Damask is only applicable to goods counting not less than 170 threads per square inch when bleached, and woven on the 8-thread or finer satin twill principle in which the weft considerably exceeds the warp in closeness." The proportion is about two warp to three weft threads Double damasks commence with about 80 ends and 90 picks per inch, from 50's/70's lea yarns. In actual trade they often have 80 ends and 120 picks per inch, and increase in multiples of five threads per inch to about 110 ends and 170 picks. An exceedingly fine linen damask contains 120 ends and 188 picks per inch, equal to 314 threads per square inch. -

2 Double Plush Weaving

The simultaneous weaving face to face of two warp pile fabrics without using wires. Each fabric has its own ground warp, but one series of warp pile threads forms the pile for both cloths. The pile threads are bound in the top and bottom cloths alternately, and after weaving are cut in the middle to form two entirely separate cloths. Usually the pile threads are severed in the loom.Dictionary of the English textile terms > Double Plush Weaving

-

3 Double Cross Stitch

In embroidery, two threads with knots over them stretched in herringbone shape, and another single thread interlacing also in herringbone effect which crosses the first threads.Dictionary of the English textile terms > Double Cross Stitch

-

4 Double-Faced Satin

A fabric with a warp satin face on both sides. Two sets of warp threads are used, with one weft series inter-weaving with both warps. Super quality yarns are often used. Heavy overcoatings are woven with the 5-shaft warp satin on both sides, and are known as double satin.Dictionary of the English textile terms > Double-Faced Satin

-

5 Cut Double Cloths

A term denoting an important class of woollen figured cloths, which is popular at times. The distinctive feature is fine furrows cutting one weave from another, and the principle is used for worsted coatings and trouserings. The cut is obtained by means of two threads arranged so that one thread is raised for two or more picks, while the other is depressed, and vice versa. -

6 сдвоенные нити

-

7 парочки

Textile: double ends, double threads (порок ткани), flats (порок ткани), spinner's doubles (порок пряжи) -

8 сдвоенные нити

Textile: double threads, marriages (дефект шёлка-сырца) -

9 Mariages

Imperfections in raw silk. They are double threads running together on the reel in winding the thread from the cocoons and which require separating by the throwster. -

10 אפפון

-

11 אֲפָפֹון

-

12 двуходова резба

double-start threaddouble-start threadsБългарски-Angleščina политехнически речник > двуходова резба

-

13 Dobby Machines

These are exceedingly useful machines for forming the shed in weaving, since they can be used for both simple and complicated weaves. There are many types in use, most of which are negative acting in so far as they only lift the healds, springs being used beneath the healds to bring them down again after being lifted by the dobby. In the cotton trade 16 up 20 jacks is usual. Dobbies in common use are known as single lift, double lift, negative, positive, open shed, closed shed, and crossborder. Single Lift - In this type there is a single knife or griffe in use to raise the heald stave. The whole of the shafts return to their original position after each pick. A fresh selection of staves to be raised is made for each pick. Looms fitted with this dobby run slower than others, about 140 picks per minute. Double Lift - These machines are fitted with double selecting and lifting parts which move at half the speed of the loom. They give an open or semi-open shed. The speed of the loom is considerably more than for the single-lift type. Crossborder - This machine is used when headings or a change of weave is required as for bordered handkerchiefs, serviettes, towels, etc. Positive - Dobby machines which make an open shed and positively lift and depress the heald staves as required by the design. Negative - Dobbies which only lift the heald staves, and require springs or other means to move the staves to the bottom position. Centre Shed - Every thread of the warp is moved for every new shed. The shed opens from the middle. Some healds ascend and the others descend. Closed Shed - So termed because all the warp threads are brought to one level after each succeeding pick as in single-lift machines. Open Shed - The type generally used for automatic looms, also the double-lift machines. After a heald stave is lifted it remains up until it is required to be down again. The warp threads constantly form two lines, upper and lower, and the only changes are when threads move from line to the other. Semi-open Shed - This shed has a stationary bottom line, and to make changes, threads pass from the top to the bottom, or from the bottom to the top. The threads which remain up for more than one pick in succession only fall halfway and then go to the top again. -

14 Jacquard Machine

The jacquard machine is an essential addition to looms intended for weaving ornamental designs that are beyond the scope of stave -work. The machine is made in many forms and sizes for different branches of the weaving industry, but its characteristic feature is that it furnishes the means whereby every individual thread in a design may weave differently from all the others. This permits the delineation of all forms and shapes and the fineness of the detail is only limited by the texture, e.g., the number of ends and picks per inch. The action of the jacquard machine is communicated to the warp threads through a system of cords known variously as the harness mounting and jacquard harness. Actually, loom harness ante-dated the jacquard machine by many centuries, and many draw loom harnesses were much more complicated than modern jacquard harnesses. An essential feature of a jacquard is that each hook in the machine can be lifted at will independently of the others. The selection of which hooks shall lift and which shall be left down is made by the designer, by painting marks on squared paper to indicate the hooks that must be lifted on each pick. In cutting the pattern cards, a hole is cut for every mark or filled square on the design paper, and a blank is left for every empty square on the paper. Assuming that each pattern card represents one pick of weft, when the card is pressed against the needles of the jacquard, the blanks push the unwanted needles and hooks out of the path of the lifting griffe; the holes allow the needles to pass through and thus remain stationary, so that the corresponding hooks remain in the path of the lifting griffe and cause the corresponding warp threads to be lifted. Jacquard: Single-lift, single-cylinder - In this machine there is only one griffe which lifts on every pick, and only one pattern cylinder, which strikes every pick. This restricts the speed at which the loom can be operated. Jacquard: Double-lift, single-cylinder - This is the machine in most common use for ordinary jacquard work. There are two lifting griffes and twice as many hooks as in a single-lift machine, but only the same number of needles and one card cylinder. The shed formed is of the semi-open type, which causes less movement of the warp threads, as any threads which require to be up for two or more picks in succession are arrested in their fall and taken up again. Double-lift jacquards give a greatly increased loom production as compared with single-lift machines, as they permit the speed of the loom to be increased to about 180 picks per minute for narrow looms, as compared with 120 to 140 picks per minute for single-lift jacquards. Jacquard: Double-lift, double-cylinder - In this machine there are two sets of hooks and needles, two lifting griffes and two card cylinders, odd picks in one set of cards and even picks in the other set. This permits maximum loom speed, it prolongs the life of the pattern cards, but is open to the serious drawback that spoiled cloth is caused whenever the two card cylinders get out of correct rotation. Jacquard: Cross Border - Fabrics with borders, such as tablecloths, bed quilts, etc., are woven with jacquards with two griffes, two sets of hooks and two card cylinders. The cards for weaving the border are laced together and weave on one cylinder, while the centre cards are on the other cylinder. The loom weaves at the speed of a single-cylinder, single-lift machine, and the change from the border to the centre cards can be made by hand or automatically

-

15 Warping

General term for processes after winding concerned in preparing weaver's and knitter's warps. Methods of warping vary according to (1) the yarns employed (2) whether they are sized or not, and (3) at what state sizing takes place. There are at least seven methods of warp preparation, e.g., beam warping, direct warping, mill warping on vertical mills, section warping on horizontal mills and in cheeses on section blocks, Scotch dresser sizing, Scotch warp dressing, and Yorkshire warp dressing. Beam Warping is the system in general use for making grey cotton goods. The beam warper comprises a creel for the supply ends, which may be on double-flanged bobbins, cones or cheeses, and a beaming head which comprises mechanism for mounting and rotating a warper's beam and means for winding the yarn from the creel supply on to the beam under suitable tension. The number of ends and length of warp on a back or warper's beam is related to what is required in the weaver's beam. Assuming the weaver's beams were required to have 2928 ends, 24's warp, and 8 cuts of 96 yards each, the back beams for a set might have 2928: 6 = 488 ends, and 2 X 6 X 8 X 96 = 9216 yards. On the slasher sizing machine six back beams would be run together, thereby producing 12 weaver's beams each containing 2928 ends 768 yards long. Warp Beaming Speeds - With the old type of warp beaming machine taking supply from unrolling double-flanged bobbins, the warping speed would be about 70 yards per minute. In modern beam warpers taking supply overend from cones, the warping speed is up to 250 yards per minute. With beam barrels of 41/2-in. dia., and up to 500 yards per minute with barrels of 10-in. dia. Warp and Weft Knitted Fabrics - Warp knitted fabrics in which extra yarn is introduced in the form of weft threads which are laid in between the warp threads and their needles for the purpose of adding extra weight and for patterning purposes. Warp Loom Tapes - Narrow knitted fabrics usually less than one inch wide used for trimming garments. They are knitted on circular latch needle machines, but the tapes are flat. Direct Warping - A method used in making warps for towels, fustians, and other fabrics in which the total number of ends can be accommodated in one creel, say not more than 1,000 ends. The threads are run from the creel direct to the weaver's beam on a machine similar to that used in section beam warping. Mill Warping - There are two distinctly different methods of mill warping. On the vertical mill, which may be anything up to 20 yards in circumference, the number of ends in the complete warp is obtained by repeating the runs the required number of times, e.g., with 200 bobbins in the creel, 4 runs would give a warp of 800 ends. The length of the warp is determined by the number of revolutions made by the mill for each run. The horizontal mill is much used in Yorkshire for making woollen and worsted warps It is used to a small extent for cotton warps and is largely used for making silk and rayon warps. The mill or swift is usually about 5 yards in circumference. Its distinctive feature is the making of warps in sections which are wound on the mill in overlapping manner. The creel capacity varies from 250 to 600 ends, and with 500 ends in the creel a warp of 5,000 ends would require ten sections. Section Warping for Coloured Goods - This is a system of making coloured striped warps from hank-dyed and bleached yarns. The bobbins are creeled to pattern, one or more complete patterns to each section. Each section is the full length of the warp and is run on a small section block keywayed to fit a key on the shaft of the subsequent beaming machine where the sections are placed side by side and run on the weaver's beam. Scotch Dresser Sizing - There are two systems of warp preparation known as Scotch dressing. 1. Dresser sizing used for sizing warps for linen damasks, etc. Back beams are first made and placed in two beam creels, one on each side of the headstock. The threads from several back beams are collected in one sheet of yarn, sized by passage through a size-box, brushed by a revolving brush, dried by hot air, and passed vertically upwards where both sheets of warp threads are united and pass on to the weaver's beam in a single sheet. Scotch Warp Dressing - The other method of Scotch dressing is used in the preparation of coloured striped warps, usually from warp-dyed and bleached yarn. It consists in splitting off from ball warps previously dyed or bleached and sized, the number of ends of each colour required in the finished warp. Each group is then wound on separate flanged warpers' beams. These beams are placed in a creel and the ends drawn through a reed according to pattern, and wound finally on to the weavers' beams. Yorkshire Warp Dressing - This is a system used mostly in the preparation of coloured striped warps. It is also invaluable in preparing warps dyed and sized in warp form to prevent shadiness in the cloth. Four warps with the same number of ends in each are dyed the same colour, and in sleying, one end from each warp is put in each dent of the reed. Any tendency to shadiness arising from irregularity in dyeing is thereby effectively eliminated. In striped work the required ends are split off if necessary from a larger ball warp, sleyed to pattern in the reed, and then run under controlled tension on to the weaver's beam. The dresser uses a brush as long as the width of the warp to brush out entangled places where the threads have adhered together with size. Yorkshire dressing provides perfect warps with every thread in its proper place on the weaver's beam, no crossed or missing threads, and a minimum of knots. -

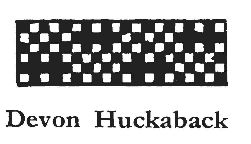

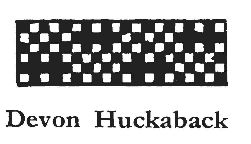

16 Devon

DEVON, or MEDICAL HUCKThis is the simplest form of huckaback weave, and is on 10 ends and 6 picks. The warp threads are usually dented three and two per dent alternately, which tends to prevent the threads splitting in the cloth and forming cracks. Woven with two picks in a shed. Woven about 58 ends and 30 double picks per inch, from 30's and 26's linen yarns, 25-in. wide cloth. Another cloth is made 26-in. wide, reed 30 porter (two and three threads alternately), reed width 281/2-in., warp 3-lb. flax (331/3 per cent loss), weft 4-lb. flax (331/3 per cent loss), 24 double shots on 37/40-in. glass, laid 111 yards, loom length 95 yards, finished length, 102 yards. These details are as usually used in the trade ————————

A heavy felted woollen overcoating cloth.

————————

A heavy felted woollen overcoating cloth. -

17 Medical Huck

DEVON, or MEDICAL HUCKThis is the simplest form of huckaback weave, and is on 10 ends and 6 picks. The warp threads are usually dented three and two per dent alternately, which tends to prevent the threads splitting in the cloth and forming cracks. Woven with two picks in a shed. Woven about 58 ends and 30 double picks per inch, from 30's and 26's linen yarns, 25-in. wide cloth. Another cloth is made 26-in. wide, reed 30 porter (two and three threads alternately), reed width 281/2-in., warp 3-lb. flax (331/3 per cent loss), weft 4-lb. flax (331/3 per cent loss), 24 double shots on 37/40-in. glass, laid 111 yards, loom length 95 yards, finished length, 102 yards. These details are as usually used in the trade ————————

Also known as Devon Huck.

————————

Also known as Devon Huck. -

18 Draft

See Drawing (Spinning) ———————— The order of drawing-in the warp threads through the eyes of the healds for weaving. The general principle is that those threads that work alike are drawn on the same stave. To avoid crowding the healds, those for weaving plain fabrics, poplins, etc., often have the ends drawn on four or six heald staves. It is a feature of weaving by healds, particularly those operated by dobbies, that very large and intricate patterns can be woven on 16 staves or less. Some drafts are so simple that they are known in the trade by name as those illustrated. Straight Over, shown at SO, in which one thread only is drawn on each stave consecutively from front to back. Skip Shaft, shown at SS, in which the threads are drawn on four staves instead of two, staves 1 and 2, and 3 and 4, being tied together to permit their operation by plain weave tappets. Point Draft, shown at P, where the first part of the draft is straight over from front to back and then returns from back to front. Double Point Draft, shown at DP, where the draft is straight over twice and from back to front twice. Broken Drafts are those not capable of being reduced to any simple regular order. See also Design, Draft and Lifting Plan. ————————

A fine, all-wool, warp ribbed cloth; used in churches during the 18th and 19th century on the Continent.

————————

A fine, all-wool, warp ribbed cloth; used in churches during the 18th and 19th century on the Continent. -

19 резьба

( по камню или дереву) carving, screw, screw thread, thread* * *резьба́ ж.1. ( винтовая поверхность как средство соединения) threadвходи́ть в зацепле́ние с резьбо́й — engage the threadзабива́ть резьбу́ — crush a threadзачища́ть наре́занную (вну́треннюю) резьбу́ метчико́м — chase the previously cut threadнака́тывать резьбу́ — roll a thread, produce a thread by rollingнареза́ть резьбу́ — cut a thread, produce a thread by cuttingнареза́ть резьбу́ метчико́м — tap a threadнареза́ть резьбу́ пла́шкой — cut threads by the die and stockнареза́ть резьбу́ червя́чной фрезо́й — cut threads by hobbingсрыва́ть резьбу́ — strip a threadшлифова́ть резьбу́ — grind a thread2. ( художественная) carving, engravingрезьба́ Ви́творта — Whitworth [inch] threadвну́тренняя резьба́ — internal [female] threadдвухзахо́дная резьба́ — double(-start) threadдюймо́вая резьба́ — inch [Whitworth] threadкони́ческая резьба́ — taper threadкрепё́жная резьба́ — screw threadкру́глая резьба́ — round threadкру́пная резьба́ — coarse threadле́вая резьба́ — left-hand threadме́лкая резьба́ — fine threadметри́ческая резьба́ — metric threadметри́ческая резьба́ по станда́рту ИСО — ISO metric threadмногозахо́дная резьба́ — multistart threadнару́жная резьба́ — external [male] threadнепо́лная резьба́ — flattened [truncated, imperfect] threadоднозахо́дная резьба́ — single(-start) threadрезьба́ по де́реву — wood carvingрезьба́ по ка́мню — stone carvingпра́вая резьба́ — right-hand threadпрямоуго́льная резьба́ — square [flat] thread«пья́ная» резьба́ — “drunken” headтрапецеида́льная резьба́ — trapezoidal threadтреуго́льная резьба́ — triangular threadтру́бная резьба́ — pipe threadупо́рная резьба́ — buttress threadцилиндри́ческая резьба́ — straight [cylindrical, parallel] threadчервя́чная резьба́ — worm thread* * * -

20 резьба

1. ж. thread2. ж. carving, engraving

См. также в других словарях:

Double checked locking — En génie logiciel, le verrouillage à double test ou double checked locking est un ancien patron de conception[1]. Considéré aujourd hui comme un antipattern du fait des problèmes subtils et difficiles à déceler qu il pose, il a été utilisé dans… … Wikipédia en Français

Double-threaded — Dou ble thread ed, a. 1. Consisting of two threads twisted together; using two threads. [1913 Webster] 2. (Mech.) Having two screw threads instead of one; said of a screw in which the pitch is equal to twice the distance between the centers of… … The Collaborative International Dictionary of English

double-threaded screw — noun (engineering) A screw having two threads, whose pitch is half the lead (also two start thread) • • • Main Entry: ↑double … Useful english dictionary

Double-checked locking — In software engineering, double checked locking (also known as double checked locking optimization[1] .) is a software design pattern used to reduce the overhead of acquiring a lock by first testing the locking criterion (the lock hint ) without… … Wikipedia

Double-checked locking — En génie logiciel, le verrouillage à double test ou double checked locking est un ancien patron de conception[1]. Considéré aujourd hui comme un antipattern du fait des problèmes subtils et difficiles à déceler qu il pose, il a été utilisé dans… … Wikipédia en Français

Double cloth — Dove and Rose jacquard woven silk and wool double cloth furnishing textile, designed by William Morris in 1879.[1] Double cloth or double weave (also doublecloth, double cloth) is a kind of woven … Wikipedia

Double checked locking — Шаблон проектирования Блокировка с двойной проверкой Double checked locking Описан в Design Patterns Нет Double checked locking (блокировка с двойной проверкой) шаблон проектирования, применяющийся в параллельном программировании. Он… … Википедия

Double-ended queue — Not to be confused with Double ended priority queue. In computer science, a double ended queue (dequeue, often abbreviated to deque, pronounced deck) is an abstract data structure that implements a queue for which elements can only be added to or … Wikipedia

Double bass — Contrabass redirects here. For other uses, see Contrabass (disambiguation). Not to be confused with Acoustic bass guitar. For the technique used in percussion, see Double bass drum. Double Bass Side and front views of a modern double bass with a… … Wikipedia

double-threaded — | ̷ ̷ ̷ ̷| ̷ ̷ ̷ ̷ adjective : consisting of two threads twisted together : having or using two threads … Useful english dictionary

double thread — noun : two parallel threads of equal dimensions on the same screw one of which is 180° ahead of the other … Useful english dictionary